Research Areas

An array of all things polymer

Asphalt Additives

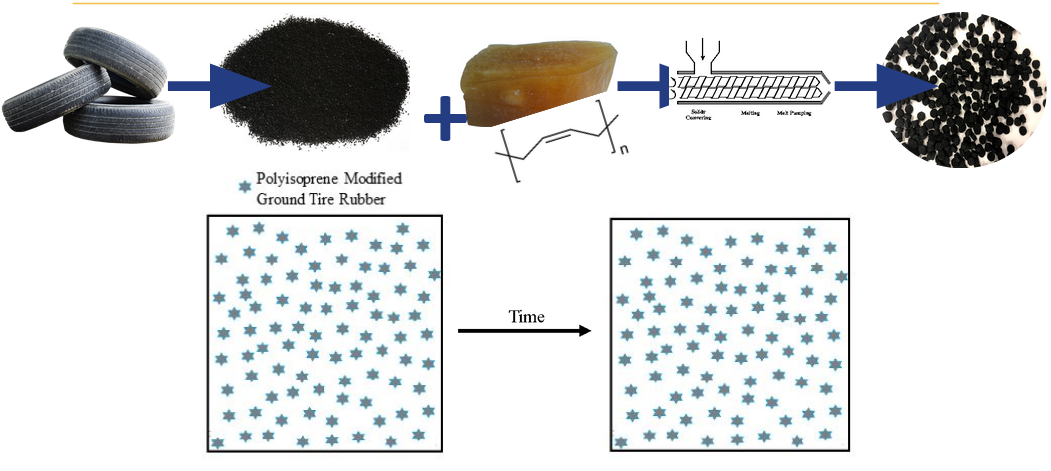

Using the RAFT process, we have shown the ability to convert soybean oil into polymers that have a tremendous benefit on asphalt pavement. Traditionally, polymer modification of asphalt is required for high traffic roads; however, the polymer used has become scarce and expensive in recent years. Our vegetable oil polymer is capable of not only extending the petroleum polymer, getting more effectiveness using less material, but also allows the use of extremely high content of recycled asphalt materials. Additionally, ground tire rubber has been used in the asphalt industry, though it suffers some very substantial performance issues in that the rubber separates from the asphalt. Our group has developed additives that prevent that separation, thus producing an asphalt with high elastic recovery without the cost of adding polymer.

Bio-derived, performance advantaged

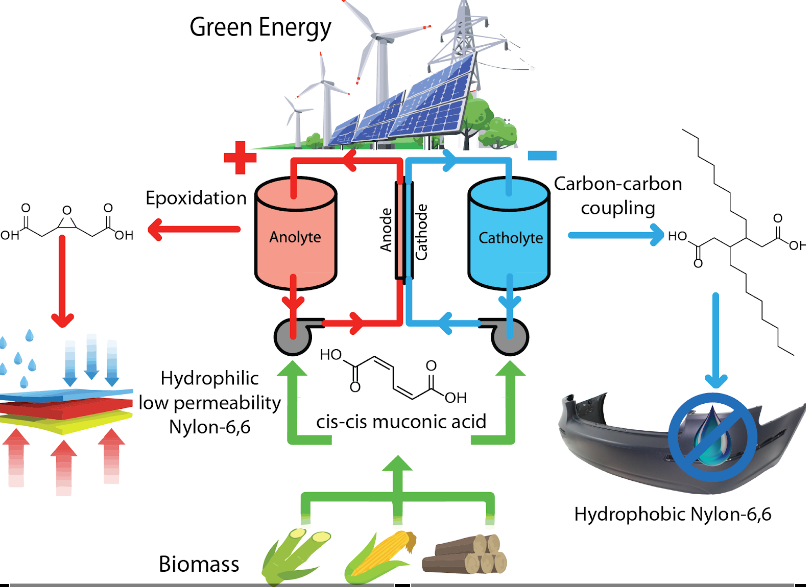

Polymers Nylon and PET are of huge importance to the plastic industry, however, we have found that introduction of biologically derived comonomers can have a tremendous positive benefit on the performance of the materials.

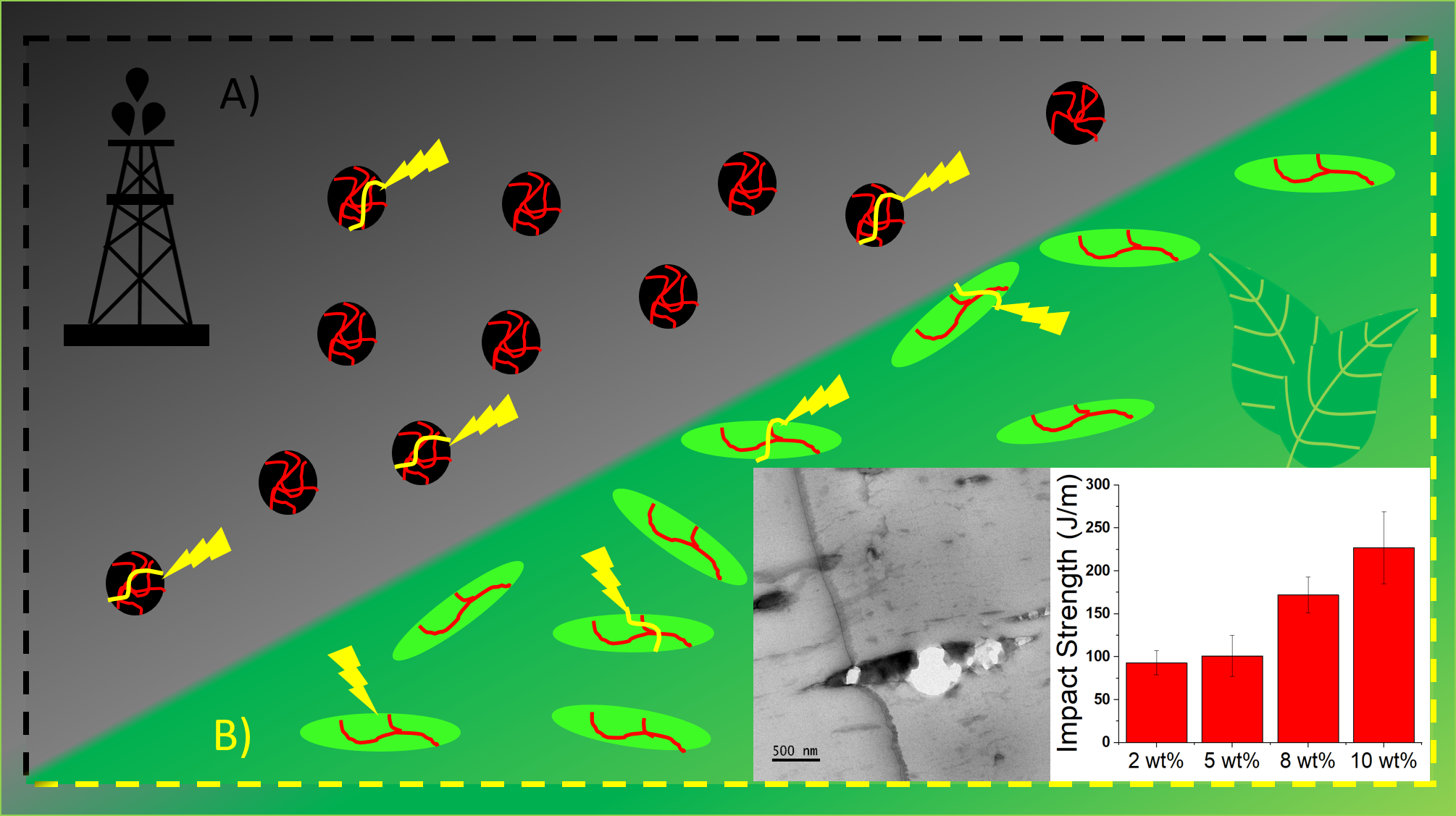

Polymer composites

Using the vegetable-oil thermoplastics, we have shown the ability to modify polyesters such as PLLA, increasing the tensile and impact toughness by an order of magnitude or more with little to no sacrifice of other material properties.

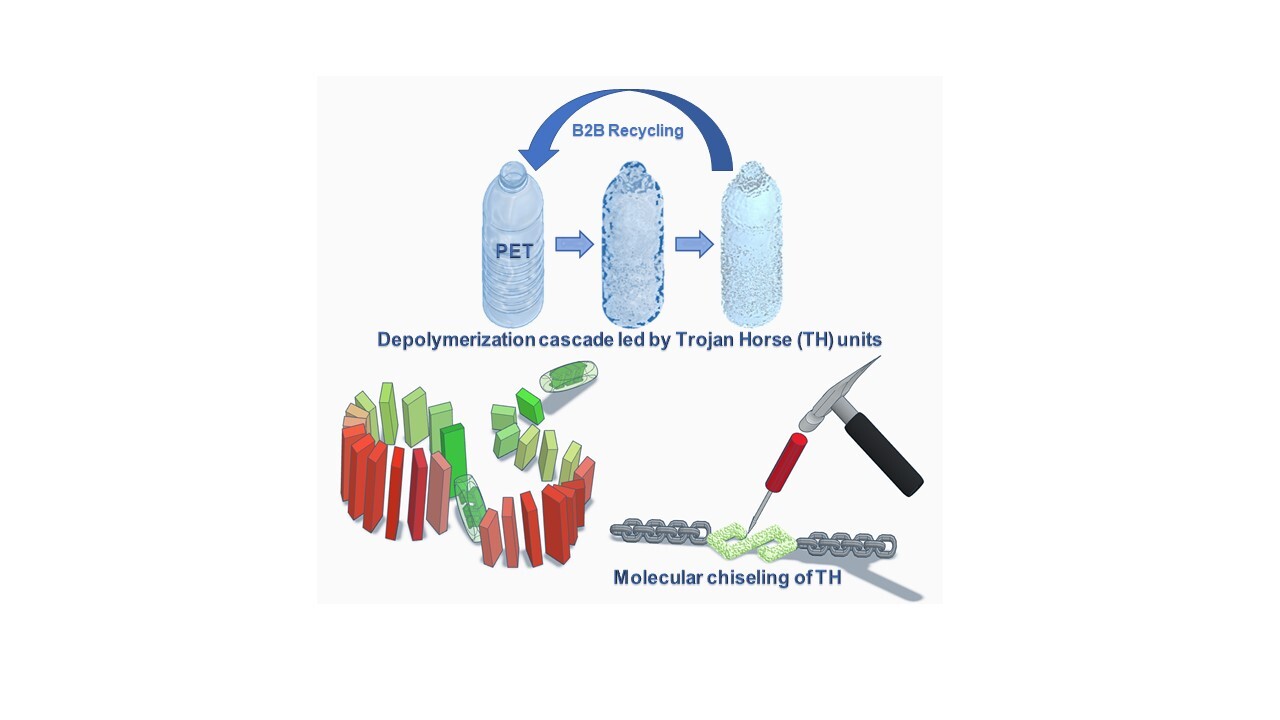

Plastic End-of-Life

Can we use techniques such as intelligent polymer chemistry design and/or reactive extrusion to make chemical recycling more energy and time efficient?

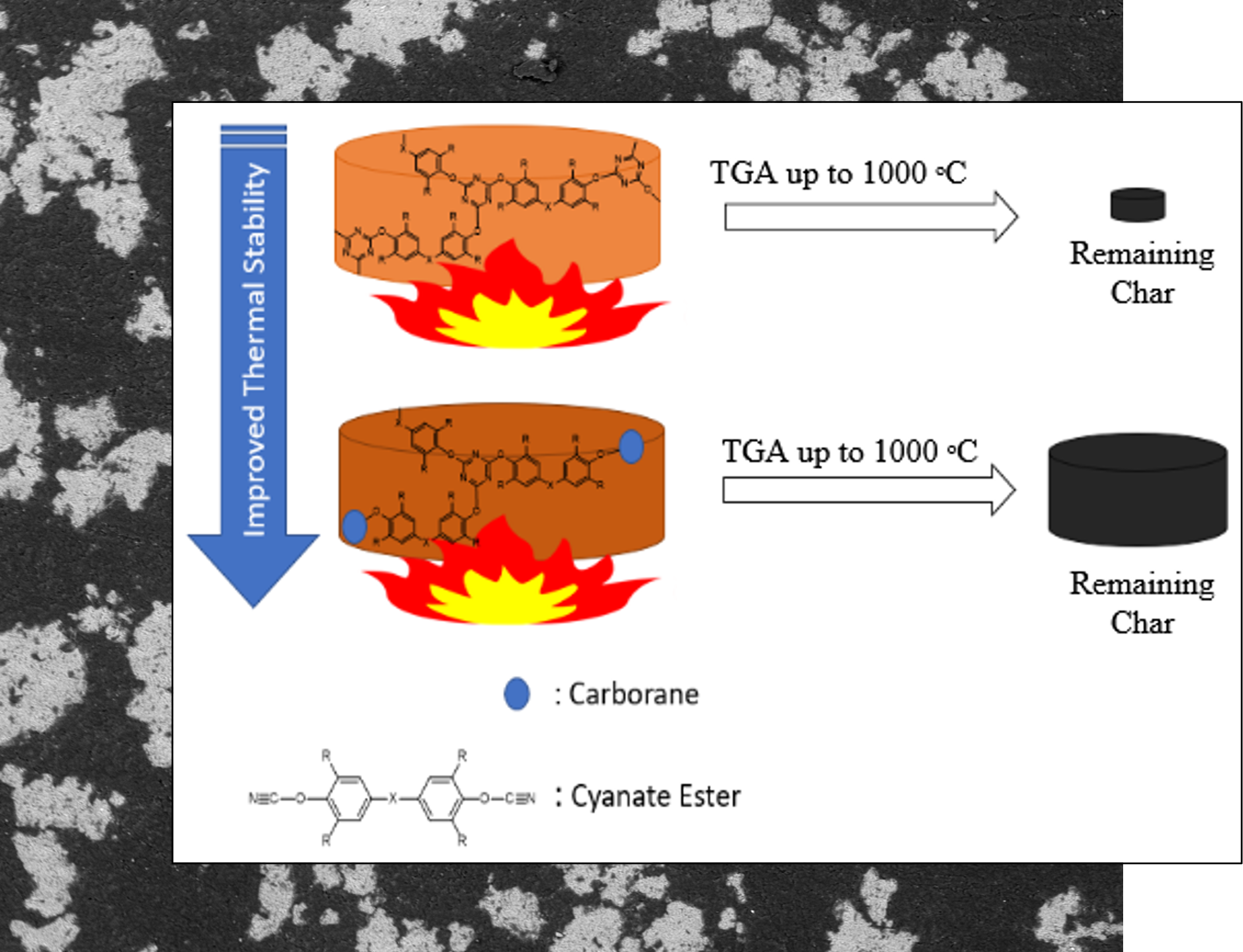

Polymer Fundamentals

In addition to applications, our group focuses on polymeric materials and systems with a focus on the resulting properties to elucidate interactions in the polymer or polymer and filler. Recently, our work has focused on thermoset resins and the properties there-from when loaded with various fillers. Understanding interactions both between polymers and particles to develop fundamental structure-property relationships is key to discovering novel and improved systems.

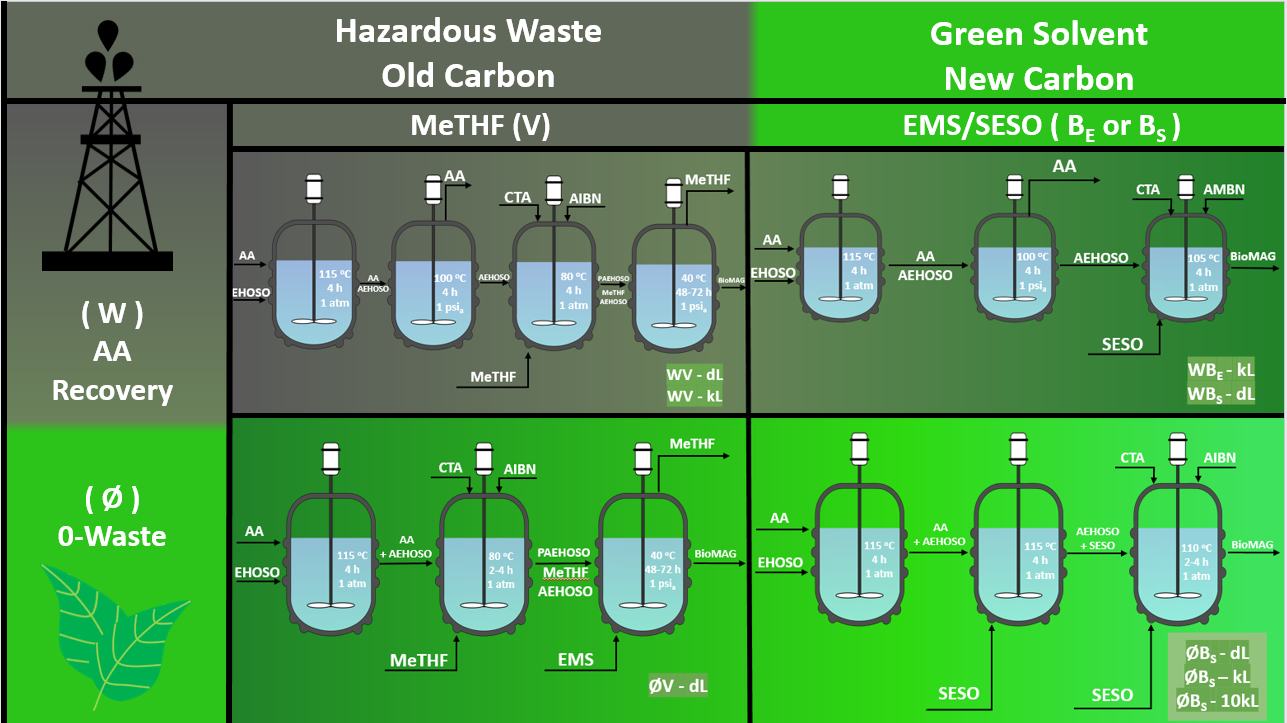

RAFT Thermoplastics in traditionally thermoset systems

Our group was the first to use reversible addition fragmentation chain transfer (RAFT) to produce thermoplastics from systems that were previously thought to be only possible to produce thermosets. We have applied this method to various different multifunctional materials such as soybean oil and glycerol to make materials that are currently in the process of being commercialized.

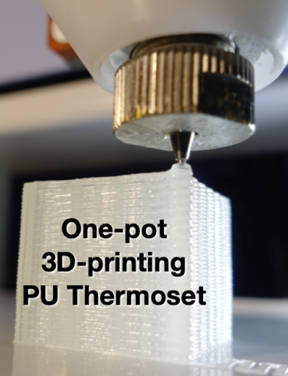

Additive Manufacturing

Additive manufacturing (AM), also known as 3D-printing (3DP), is a highly potential next-generation manufacturing technique based on the make-to-produce concept. Our current target is to tackle the challenge of 3D-printing non-conventional polymers, like thermosets including polyurethane (PU) and epoxy. We have designed a series of 3D-printable one-pot PU and epoxy nanocomposites with inorganic and all-polymer additives, which can be 3D-printed via the direct-ink writing (DIW) method. We are also working on exploring fundamental properties and structure-property relationships to extend current concepts to other polymer systems and potential applications.